Group ND Proposal

Engine Block and related

The engine block may be original for the model or changed to a later casting/version from the same manufacturer of the vehicle model, provided it :-

- Is made from the same type of material, eg Aluminium alloy or cast iron

- Has identical cylinder bore, crank stroke and crankshaft tunnel sizes

- Has identical main cap fixtures and locations

- Has identical cylinder head fixtures and locations

- Accepts the original camshaft drive system, oil pump, ignition distributor (if fitted to the block)

- Accepts identical engine mounting and support brackets

- Has the same engine model code allocated by the manufacturer

All rotating and reciprocating parts inside the engine block are free save that the crankshaft stroke cannot be altered

The engine mechanical water pump and its drive system is free . Cooling system hoses are free .

Balancing, coating, polishing, surface refinishing , electroplating and heat treatment of any internal component is free.

The block must not be externally altered by grinding off unwanted segments, brackets, manufacturer Identification marks etc.

Cylinder Head

The cylinder head may be a later casting/version from the same manufacturer or a more modern reproduction or performance oriented alternative that may have different size or shape ports.

Where a non original head is adopted, the intake and exhaust port numbers , general location (ie, on which side of the head), number of head studs/bolts and any cam shaft drive system must not change from that which was original for the MODEL.

All rotating and reciprocating parts inside the cylinder head are free.

Fixed devices located under the valve or rocker covers ,such as rocker support posts, are free.

Emission control devices such as EGR valves, are free.

Valve Actuation

Any valve operation system may be freely modified to allow adjustment of the static timing, however the basic method of operation must not change, eg chain drive cannot be swapped for belt drive or gear drive or vice-versa. Belts, chains and tensioning devices are otherwise free.

Valves, valve springs, rocker arms , rocker pedestals , cam buckets , retaining collets and any related packers or shim, are free . Any variable cam timing or valve lift system is free.

Justification and Rationale

The combination of Group N general requirements + this Nc section are seen as too proscriptive and detrimental to wider competitor uptake, especially for a newer cohort or racers with a new generation of more complex vehicles.

Many of the period MODEL have a vast range of competition parts already available off the shelf

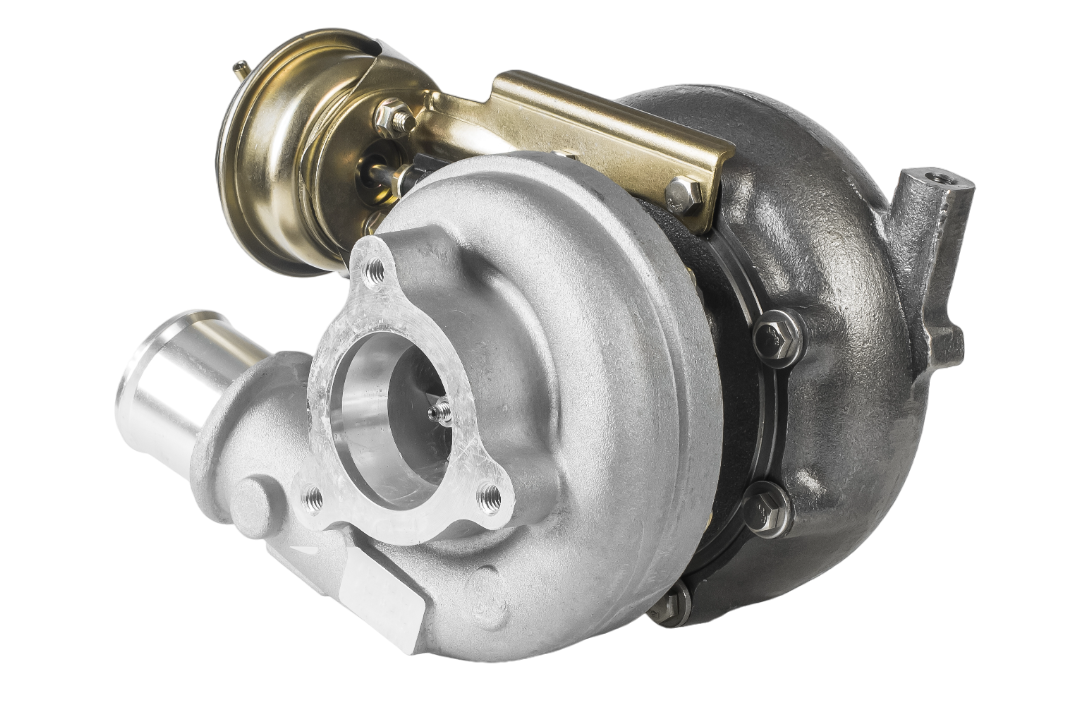

The suggested new Nd rules are more complex because the cars and engines of Nd era are more complex with widespread introduction of multiple overhead cams, electronic injection, turbocharging etc and the nature of modifications commonly seen on Nd era cars. A balance has been sought between trying to stay largely “original” (which can drive up costs) and having extensive freedoms to swap engines akin to Sports Sedans or even 3J IP .